Northern Green Crane to supply hydrogen from Sweden by 2026

Northern Green Crane provides a unique hydrogen network connecting low-cost green hydrogen sources.

Northern Green Crane will become one of the first industrial-scale green hydrogen import projects for Germany and the Netherlands.

By establishing green hydrogen production in Sweden, the project is renamed, Northern Green Crane. The access to the source in Sweden significantly improves the former Green Crane project, and all landing points remain as planned by Hydrogenious LOHC Technologies with its industry partners Royal Vopak and the Get H2 initiative in Germany.

Northern Green Crane and its partners are applying for the ‘Important Projects of Common European Interest (IPCEIs) funding scheme. All project applications have been submitted within the RHATL wave (Regional Hubs and Their Links) to the European Commission for approval.

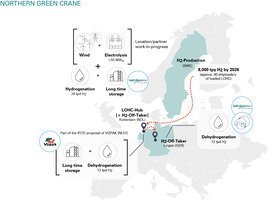

Northern Green Crane will be one of the first projects to import green hydrogen at an industrial scale to the Netherlands and Germany by 2026. By using existing liquid fuel infrastructure, the project enables the acceleration of import activities, providing up to 8,000 tonnes of green hydrogen per year. It will lay strong stepping stones for future large-scale imports via LOHC, accessing low-cost green hydrogen sources and providing crucial conditions for the decarbonization of industry and mobility.

It strengthens the landing locations in Germany and the Netherlands. Sweden, as a producing country, is characterized by its great renewable energy potential, including hydro and wind power, excellent corresponding infrastructure and industry players.

The project will be realized by storing green hydrogen in Liquid Organic Hydrogen Carrier (carrier material benzyl toluene) in Sweden with a 24-tonnes-hydrogen-per-day hydrogenation plant from Hydrogenious LOHC Technologies. Via approximately 40 shiploads per year, the LOHC loaded with hydrogen will be transported from Sweden to the Netherlands.

In Rotterdam, half of the hydrogen will be released in a newly 12-tonnes-hydrogen-per-day Hydrogenious LOHC’ dehydrogenation plant to reach industry in the port and hinterland region. The other half of the hydrogen-loaded LOHC will be transported using barge via the river Ems to Lingen/Germany. There, the hydrogen will be released from the LOHC in another 12-tonnes-hydrogen-per-day Hydrogenious LOHC’ dehydrogenation plant, used by local industry, and fed into a hydrogen pipeline as part of the GET H2 initiative.