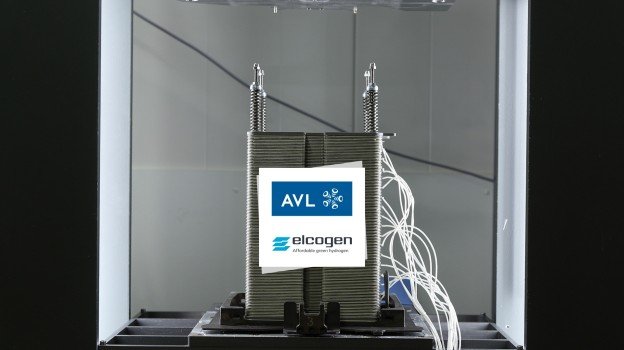

lcogen partners with AVL to develop MW scale SOEC stack modules for hydrogen production plants

Elcogen, a leading European manufacturer of technology that enables the delivery of efficient, affordable green hydrogen and emission-free electricity, is pleased to announce a partnership with global technology company AVL List GmbH to develop solid oxide electrolyser cell (“SOEC”) stack modules for MW scale hydrogen production plants. This project brings together the R&D efforts of both partners in their respective IPCEI (“Important Project of Common European Interest”) Hy2Tech programs in Estonia/Finland and Austria.

AVL, headquartered in Graz, Austria, is one of the world’s leading mobility technology companies for development, simulation and testing in the automotive industry, and in other sectors such as rail, marine, and energy. AVL delivers concepts, technology solutions, methodologies and development tools for a greener, safer, better world of mobility and beyond. AVL has 12,200 employees at more than 90 locations and 45 Tech and Engineering Centers worldwide.

The partners will focus on one of the biggest challenges of the technology – to scale from small cell footprints to multi-megawatt modules. The solution will incorporate multiple Elcogen single SOEC stacks in a stack module which will enable industrial scaling of the technology. The collaboration combines Elcogen’s leading-edge technology in SOEC/solid oxide fuel cell (“SOFC”) cells and stacks with AVL’s industry-leading expertise in SOFC/SOEC systems and stack module development.

SOEC is a game-changing electrolyser technology enabling intrinsic higher efficiencies compared to Alkaline, PEM or AEM electrolysers. Moreover, when SOEC is coupled to external heat sources from industrial processes, efficiencies in the range of 90% and beyond can be achieved. This advantage makes SOEC the technology of choice in industrial hydrogen production and also in e-fuel production, especially where the exhaust heat of the synthesis process can be used.

Martin Skov Skjøth-Rasmussen said, “Through this collaboration and combination of complementary specialised expertise under the IPCEI Hy2Tech program, we hope to accelerate the development of modular solutions for the industrial scale deployment of solid oxide technology.”

Jürgen Rechberger added, “We are happy to join forces under the umbrella of IPCEI Hy2Tech with Elcogen. Together we will address the key challenge of industrialising SOEC –the scale-up to industrial-relevant module sizes. We look forward to developing this stack module solution with Elcogen and demonstrating it in our IPCEI Hy2Tech program.”