Bosch tests hydrogen fuel cell vans

The fuel cell enables long ranges and short refuelling times, which makes long journeys more economical.

Bosch has now equipped two vans with fuel cell technology and started test operations on the road.

The partner in the project is ABT eLine GmbH, which designed and converted the vehicles together with Bosch Engineering GmbH. At IAA Transportation in Hanover, Bosch is offering interested visitors the opportunity to experience the test vehicles and Bosch fuel cell technology in action on a track.

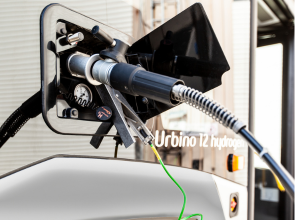

The developers could use Bosch components almost throughout the fuel cell system. A fuel cell kit is used, which comprises the stack, anode supply module including hydrogen gas injector and recirculation blower, electronic control unit, electric air compressor and components for the hydrogen storage system, and even a large number of sensors. The technical basis for both vehicles is commercially available vans that run on electric power alone. The batteries, including peripherals, were now replaced by the fuel cell, five storage tanks for a total of over 22 pounds of hydrogen, and a smaller lithium-ion battery.

The partner ABT eLine adapted the cooling system, the vehicle control system, and the electrical system. Bosch designed the fuel cell system, integrated it into the vehicle with the hydrogen storage system, and developed the associated control system. After the required technical tests, the vehicles were granted official approval for road use.

The project is already providing important insights: even loaded, the vehicles can travel up to 335 miles and are fully refuelled again in six minutes. The fuel cell can therefore be a good addition to the battery-electric drive in future for fleet operators whose vans cover particularly long distances during the day and return to the maintenance and storage facility in the evening.

The first Bosch components for fuel cells are already in volume production. But the work is far from over. Bosch needs more data from real driving operations to develop the system further. Thanks to cloud connectivity, the two test vehicles now deliver these in real-time to the developers’ computers, supplementing the measured values from the test benches. With this knowledge, Bosch can offer customers components that have been tried and tested even earlier and comprehensive support in system design.

Dr Markus Heyn, a member of the Bosch board of management, said, “With the two fuel cell vans, we are expanding our understanding of the system and showing that the fuel cell can also be a suitable drive solution for light commercial vehicles.”

Dr Uwe Gackstatter, president of the Bosch Powertrain Solutions division, said, “Accommodating the fuel cell components in the available installation space was a major challenge.”