BMW starts production of fuel cells for BMW iX5 Hydrogen

BMW Group commences in-house production of fuel cells for BMW iX5 Hydrogen in Munich, Germany.

The combination of fuel cell and battery is set to enrich the company’s portfolio by adding a unique form of drive system for the premium segment. The BMW Group is playing a visionary and pioneering role in this technology with the aim of achieving a more diversified transition to zero-emission mobility.

Oliver Zipse, Chairman of the Board of Management of BMW AG, said, “By commencing small-scale production of fuel cells today, we are demonstrating the technical maturity of this type of drive system and underscoring its potential for the future.”

Frank Weber, Member of the Board of Management of BMW AG, Development, said, “We have managed to more than double the fuel cell’s continuous output in the second-generation fuel cell in the BMW iX5 Hydrogen, while weight and size have both decreased drastically.”

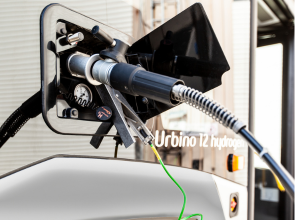

This technology is one of the core elements in the BMW iX5 Hydrogen and generates a high continuous output of 125 kW/170 hp. It teams up with an electric motor featuring fifth-generation BMW eDrive technology and a high-performance battery purpose developed for this vehicle to enable its powertrain to deliver 275 kW/374 hp. The development team incorporated the powerful drive system – comprising two hydrogen tanks, the fuel cell and the electric motor – into the existing BMW X5 platform for the small production run.

The BMW iX5 Hydrogen already successfully demonstrated its excellent everyday usability, even at very low temperatures, during the final round of winter testing in Sweden at the start of this year.

The BMW Group sources the individual fuel cells required for manufacturing the BMW iX5 Hydrogen from the Toyota Motor Corporation. The two companies have enjoyed a partnership and collaborated on fuel cell drive systems since 2013.

The stack housing is manufactured in the light metal foundry at BMW Group Plant Landshut using a sand casting technique. For this, molten aluminium is poured into a mould made from compacted sand mixed with resin in a process specially designed for this small-series vehicle. The pressure plate, which delivers hydrogen and oxygen to the fuel cell stack, is made from cast plastic parts, light-alloy castings, and the Landshut plant. The pressure plate forms a gas-tight and water-tight seal around the stack housing.