Rejected energy: can we save it from being wasted?

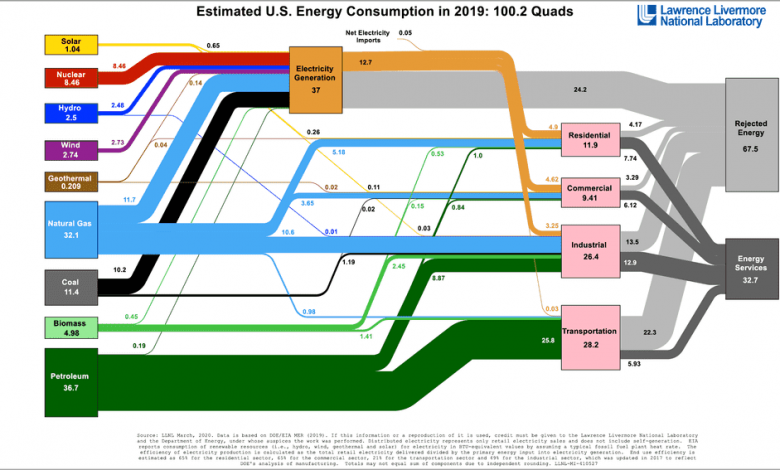

Have you heard about the term ‘rejected energy’? That is right. It is the part of the energy which is produced but not used. When we use fuel such as diesel or natural gas, we are unable to use all the utilised energy for the intended purpose, a portion escapes in the form of heat. The above chart shows the scale and sources of rejected energy in the US. Indeed the waste is astonishingly high. Can we do something about it?

A lot of work is progressing around how to tackle this issue. We have recently looked into E-Fuel Corporation, a US company working on the rejected energy project. E-Fuel Corp works on Rejected Energy Reactor (RER) product which will generate electrical power and hydrogen from E100% ethanol providing the first carbon-negative hydrogen.

We interviewed Thomas J. Quinn, the Chairman and CEO of E-Fuel Corporation. We asked him a few questions about his product and how it can help the environment. The E-Fuel Corporation was founded in 2008 by entrepreneur Tom Quinn and ethanol fuel CTO Floyd Butterfield to research rejected energy so consumers, businesses and large manufacturers could break their dependence on oil.

H2 Bulletin: Please tell us about your product, and how does it work?

Tom Quinn: E-Fuel has become the most advance experienced company to combat the major causes behind Climate Change. Lawrence Livermore National Laboratory and US Department of Energy’s Energy Consumption Rate Chart reported in 2019 states that rejected energy contributed 67.5% emissions from the electrical power industry. It does not include transportation or aviation industries (which means the number could be a lot worse). This Climate Change data reported by the DOE is substantially worse than other reported scientific climate data. E-Fuel’s mission became to capture and repurpose this energy into useful mechanical energy.

H2 Bulletin: How is the E-Fuel reactor different from some of the existing technologies such as CHP?

Tom Quinn: CHP technologies are not reactor-based and therefore cannot capture rejected energy. E-Fuel’s Rejected Energy Reactor system is the world’s first rejected energy recapture technology device.

H2 Bulletin: Is the technology scalable?

Tom Quinn: Yes, they are transportable in size and can be produced within 30 minutes, for each production line, when in high-volume production. They can also be daisy-chained together, in energy cages, to produce kilowatts to gigawatts, or abundant fuels, to meet any energy demand. The RER energy cage also provides redundancy RER protection for reliable fault-tolerant operation.

H2 Bulletin: Can it be integrated with other technologies, or is it working in isolation? For instance, fitted in an automobile or as a part of boiler etc

Tom Quinn: The first-generation reactors have been designed to phase out fuel refineries and power grid substations by moving production to local facilities (similar in the way the microcomputer phased out the mainframe computer). It should be noted that the fuel and chemical industry, within itself, is the largest energy consumer of energy and their own product. By targeting this industry sector first, we can cool the planet amazingly fast.

The RER contains its own proprietary MicroFueler refinery system combined with an integrated power production system. Yes, in the future, RERs can be directly integrated into transportation vehicles, marine freight, aviation, and aerospace industries.

H2 Bulletin: Which fuel will the E-Fuel use? If it is a fossil fuel, then how would it tackle carbon emission? How the waste/by-product would be handled?

Tom Quinn: First, during my college lectures, I begin telling students and professors that there are no fossils in fossil fuels which has been proven by scientist over the past 50 years. Historical records show that John D Rockefeller coined the marketing term “fossil fuels” when asked what he uses to make his kerosene and gasoline products.

The RER’s liquid carbon captured process is not a waste (because it contains value) but rather can be sold to greenhouse agriculture growers to stimulate their plant growth. The RER will produce electrical power and hydrogen from E100% ethanol which will provide the first carbon-negative hydrogen and ethanol fuel market of products.

For kerosene jet-fuel, the RER will use crude oil, with RERs carbon-negative extraction process, to comply with ASTM Specification for Aviation Turbine Fuels D 1655. It will also make E-Fuel’s jet-fuel the first carbon-negative fuel and lowest cost aviation fuel on the market!

H2 Bulletin: What is the cost per unit of the energy it produces, and how does it go with the market prices?

Tom Quinn: E-Fuel’s go-to-market strategy, is to create an international utility service, using local invested partnerships, to manage installation, ethanol beer/oil delivery and service maintenance for the RER equipment. Customers will be charged for the initial installation and then a competitive monthly energy rate price. E-Fuel has a major advantage over its competition because two-thirds of our rejected energy has zero cost, which allows E-Fuel to undercut its energy market prices substantially.

H2 Bulletin: Have you set up any pricing structure for E-Fuel unit and how cost-effective would it be compared to the industrial boilers or other power/heat generation technologies?

Tom Quinn: We will not be selling the RER units, as mentioned before. The RER primary purpose is to produce power and fuels, which would make boilers irrelevant since RER can undercut the cost and emissions compared to boilers. In most markets, the RER monthly energy rates could be well below market price.

H2 Bulletin: Anything else you want to add?

Tom Quinn: I would emphasise by utilising “the free cost of rejected energy” the existing traditional energy markets “could or should cease to exist in the future”. This is a very disruptive technology to the entire energy marketplace, that will solve climate change very quickly.

One Comment