Japanese consortium completes hydrogen supply chain demonstration System

Chiyoda Corporation, a Japanese engineering company, specialised in oil and gas industry, has completed the first global hydrogen supply chain system demonstration partnering with Mitsubishi Corporation, Mitsui & Co. Ltd and NYK Line.

The demonstration project was launched in 2015 by the Advanced Hydrogen Energy Chain Association for Technology Development (AHEAD) which was subsidised by the New Energy and Industrial Technology Development Organization (NEDO).

The project conducted a feasibility study of the transporting and storing over 100 tonnes of hydrogen over ten months. The demonstration validated that the supply system is technically ready for commercial use. Chiyoda is now aiming to expand the system through semi commercialisation.

The second phase (2017-2020) was a feasibility study of the global hydrogen supply chain by looking into factors such as design, procurement, construction and operation of facilities. This 2nd stage was based on the previous study conducted in the first phase (2015–2017).

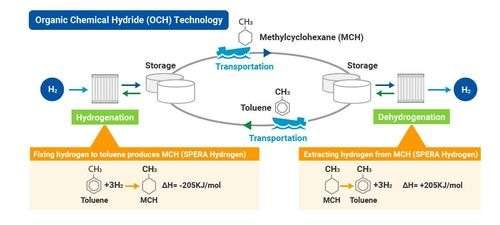

The hydrogen supply chain aims to make the existing infrastructure efficient and meet the international safety standards, monitoring the procurement & transportation process and distribution whilst using Chiyoda’s SPERA Hydrogen technology.

Hydrogen as liquid methylcyclohexane (MCH), produced from toluene and hydrogen, can be safely and economically stored and transported. Both toluene and MCH are maintained in a liquid state at ambient temperatures and pressures. Chiyoda registered MCH including hydrogen for storage and transportation as the trade name SPERA Hydrogen.